Biomass Power Plants

Biomass Power Plant

-

TOP

-

Business Domains

- Biomass Power Plants

Do you have any concerns like this?

It takes time to grasp the trouble situations occurring in the plant

Want to predict abnormalities

Business standardization has not been done

Want to manage and grasp the situation of multiple plants collectively

Variability in fuel quality Fuel instability

Although equipment inspection/maintenance tasks are outsourced to external parties, is it possible to optimize?

Your concerns

can be solved

can be solved

Through overwhelming data analysis and thorough visualization, optimize biomass power generation.

"BMecomo" is a comprehensive information platform that analyzes all data obtained from biomass power plants and supports the resolution of various challenges faced by biomass power plants. Leveraging the latest technology, we propose unprecedented management of biomass power plants.

01

Thorough visualization

- Remote monitoring dashboard

- Centralized data management

- isualization of on-site work

02

Improvement in operational efficiency

- Optimization of operations

- Reduction of downtime during troubleshooting

- Understanding operational precursors

03

Optimization of maintenance costs

- Failure prediction

- Extension of statutory inspection/audit deadlines

01

Thorough visualization

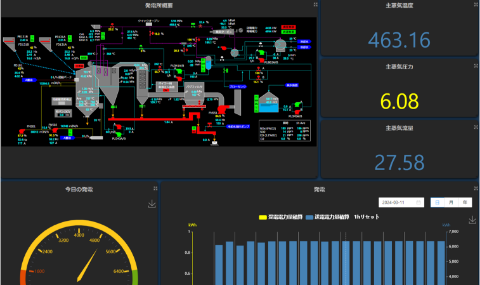

Remote monitoring Dashboard

We provide a dashboard that allows you to monitor the operational status of the plant from anywhere, at any time.

Centralized data management

We centralize various information managed in a decentralized manner within the power plant onto the BMecomo database, enabling quick access to information whenever needed.

Additionally, we digitize and store data that was previously managed on paper.

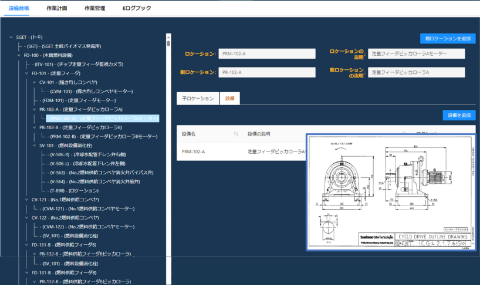

Visualization of on-site work

Today's tasks are listed, and their progress can be checked in real-time.

This eliminates subjective variations in operations and facility management tasks, leading to increased operational efficiency.

02

Improvement in operational efficiency

Optimization of operations

It is possible to create models that understand plant characteristics from vast amounts of past data and predict future operational conditions.

Additionally, the expertise of skilled operators can be incorporated into the model.

Reduction of downtime during troubleshooting

In the event of a malfunction, alert emails are sent to the specified email address, allowing instant recognition of abnormalities from remote locations.

Additionally, even if the technical manager is not present at the power plant, the speed of identifying abnormal occurrences and conveying information during work instructions is improved through the dashboard, contributing to reduced plant downtime.

Understanding operational precursors

By capturing temperature increases in boiler facilities through various sensors and AI-based predictive models, we reduce the load on boiler equipment caused by sudden changes in combustion temperature due to the characteristic variations of biomass fuel (calorific value, moisture content).

03

Optimization of maintenance costs

Fault prediction

We support the reduction of equipment repair costs by analyzing equipment data and understanding the condition of the facilities.

Extension of statutory inspection/audit deadlines

We standardize and streamline inspection tasks while centrally managing past inspection records for improved efficiency.

Key features

Function

Centralized data management

We centrally manage all data related to the plant, including past operational histories and equipment data.

System integration

We perform system integration with plant control systems and various sensor data.

Remote monitoring

We provide a dedicated dashboard that allows you to monitor the operational status of the plant from anywhere, at any time.

Alerts

Users can set up alerts and create trend graphs as needed, notifying relevant stakeholders of any signs of abnormalities in real-time.

Dedicated mobile application

We provide a dedicated app that allows for centralized management and operation of patrol inspections, work instructions, and alert information.

Data analysis

We conduct data analysis from various perspectives, providing data analysis and feedback tailored to the needs of our customers, optimizing plant operations.

Advanced equipment management

We provide advanced equipment management functionality called AMM (Asset Maintenance Management) to optimize facility management.

Sensor solutions

We offer services for various phases including sensor selection, data integration, system development, and data analysis.

Benefits of implementation

Merit

Merit 01

Passing down the expertise of craftsmen to the next generation

As population decline and depopulation of regions outside major metropolitan areas accelerate, securing skilled operators becomes a significant challenge. BMecomo addresses this by replicating the expertise of skilled operators within the system, standardizing variations caused by individual differences among operators, and facilitating the transfer of knowledge to the next generation, thereby supporting long-term stable operations.

Merit 02

Optimization of O&M (Operations and Maintenance) costs

Unforeseen accidents or equipment failures significantly decrease the plants operational efficiency. BMecomo reduces unforeseen troubles by understanding the plants condition and predicting its behavior, thereby improving operational efficiency. This support not only reduces maintenance costs but also maximizes revenue through increased operational efficiency.

Merit 03

Root cause analysis and action plan development

By leveraging the data accumulated in BMecomo, it becomes possible to analyze troubles that were previously difficult to understand due to lack of data. Through multidimensional data analysis, we identify the causes of trouble and propose effective action plans.

Inquiries

Contact

Please feel free to contact us here for any inquiries or to request materials.

For inquiries via phone, please contact us here.

[Reception Hours] Monday to Friday / 9:00 to 17:00 (Closed on Saturdays, Sundays, and public holidays)

For inquiries via the web, please use the following link.

Inquiry form